Made In America

Weather Closure Notice: Due to current weather conditions and for the safety of our staff, WISPR Systems offices are closed today and until further notice.

Made In America

Concrete has three undeniable truths: it’s gray, it’s hard and it cracks. Whether it’s a highway, airport runway, parking lot, dam or other large concrete structure, cracks are inevitable. However, catching them early can save millions in repairs and extend a structure’s lifespan.

For years, documenting cracks was a slow, manual and error-prone process. Inspectors walked miles of pavement, sketching locations, estimating measurements and hoping nothing was missed. Today, WISPR Systems is helping change the game.

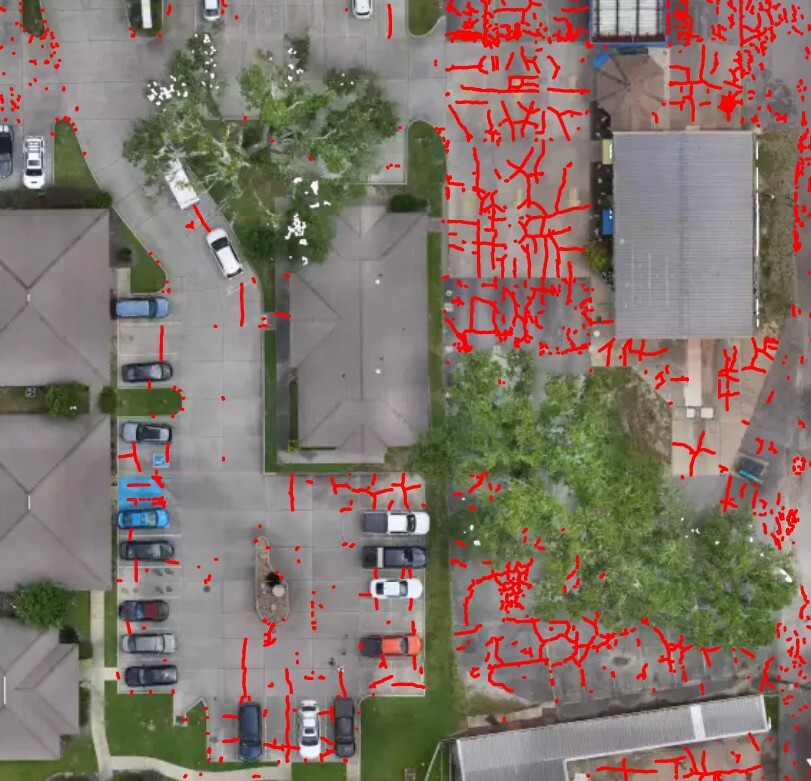

By pairing the WISPR SkyScout drone with the Sony LR1 high-resolution payload and gNexts’ advanced AI mapping software, crack detection and monitoring have become faster, more accurate and more consistent.

“With the SkyScout, Sony LR1 and gNext, we’re giving inspectors and engineers a toolset that removes the guesswork,” said Karson Kall, Director of Sales Engineering for WISPR Systems. “You’re not just spotting cracks — you’re measuring their length, width and even volume, all georeferenced to the exact location so you can come back to the same spot over time.”

Why Early Detection Matters

Cracks aren’t just cosmetic. They can indicate deeper problems such as corrosion in reinforcing steel or erosion of the base material that can compromise structural integrity.

“When reinforcing steel corrodes, it expands, and that expansion forces the concrete apart, accelerating damage,” Kall said. “The sooner you can identify changes in crack size, the sooner you can intervene before a small issue becomes a major repair.”

Precision Meets Efficiency

Once the drone imagery is processed in gNext, AI identifies and maps every crack, patch and area of spalling concrete, even vegetation encroaching on panels. Each crack is given a unique ID number, along with its dimensions.

“You can click on any crack in the system and instantly see all the data,” Kall said. “It’s exportable to Excel or CAD, filterable by minimum width and completely georeferenced, which means you can navigate straight to it in the field using a survey rover. That’s powerful.”

From Weeks to Hours

Traditional inspections might take days or weeks to complete on large projects. With the WISPR SkyScout, Sony LR1 and gNexts’ AI processing, that time can be cut down to hours.

“This isn’t just about saving time — it’s about making inspections repeatable and reliable,” Kall said. “When you can revisit the exact same crack a year later and see how it’s changed, you’re not guessing anymore. You’re making data-driven decisions.”

Protecting Infrastructure Investments

From DOTs to airport authorities and facility managers, infrastructure owners are under constant pressure to extend asset life while controlling costs.

“Our goal is to give professionals the clarity and confidence they need to maintain their infrastructure proactively,” Kall said. “This technology is another way WISPR is empowering professionals to work smarter, safer, and more effectively.”

To learn more about the WISPR SkyScout, click here.

Cracking 1

With world-class training and support, owning one of our WISPR Systems American-made drones means years of productive and well-supported flying.